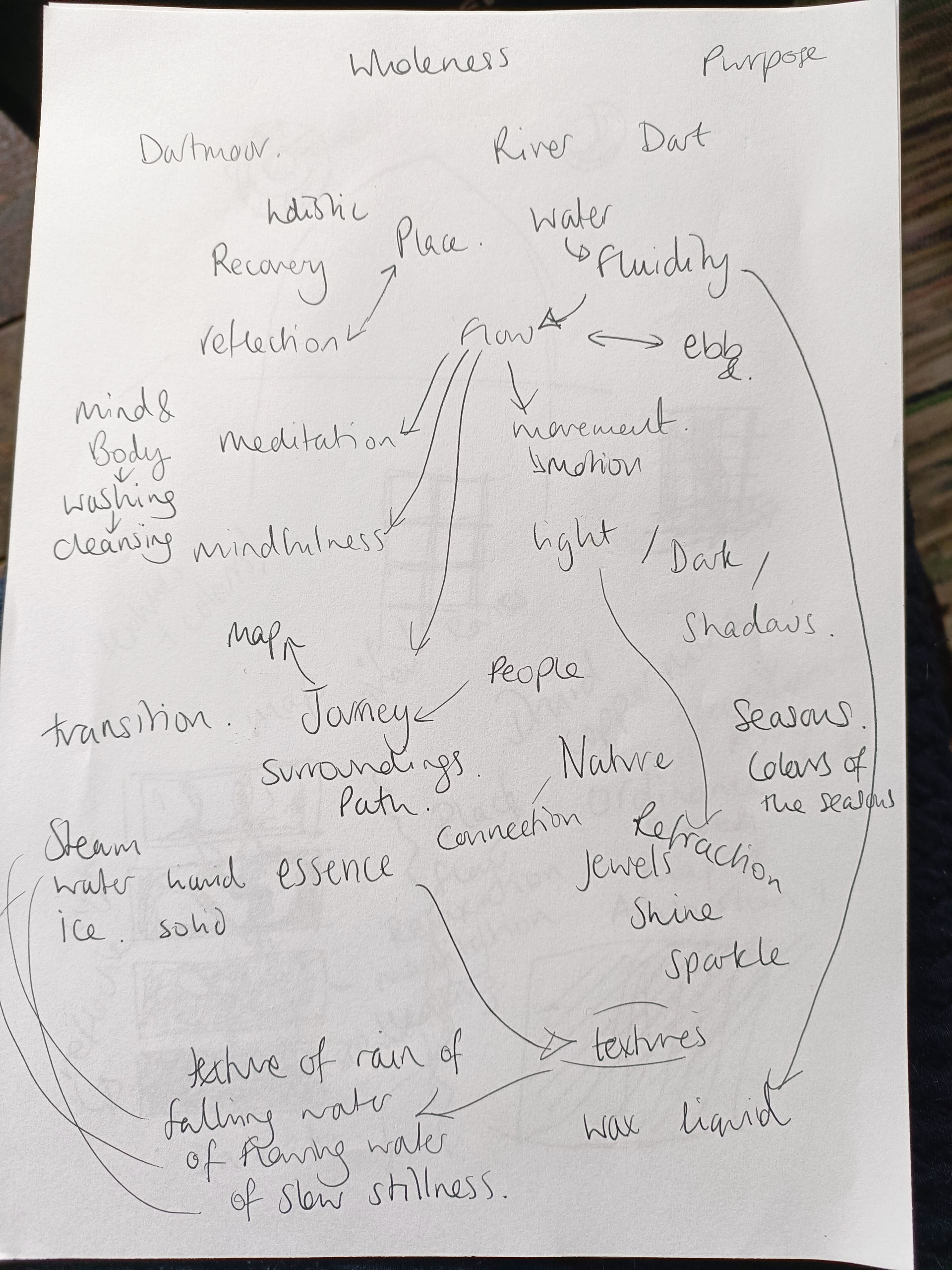

Ashburton And Buckfastleigh Health and Well Being Centre -Capturing Place in Glass: The Design Process Behind ‘Diamond River’

The Design Process behind 'Diamond River'

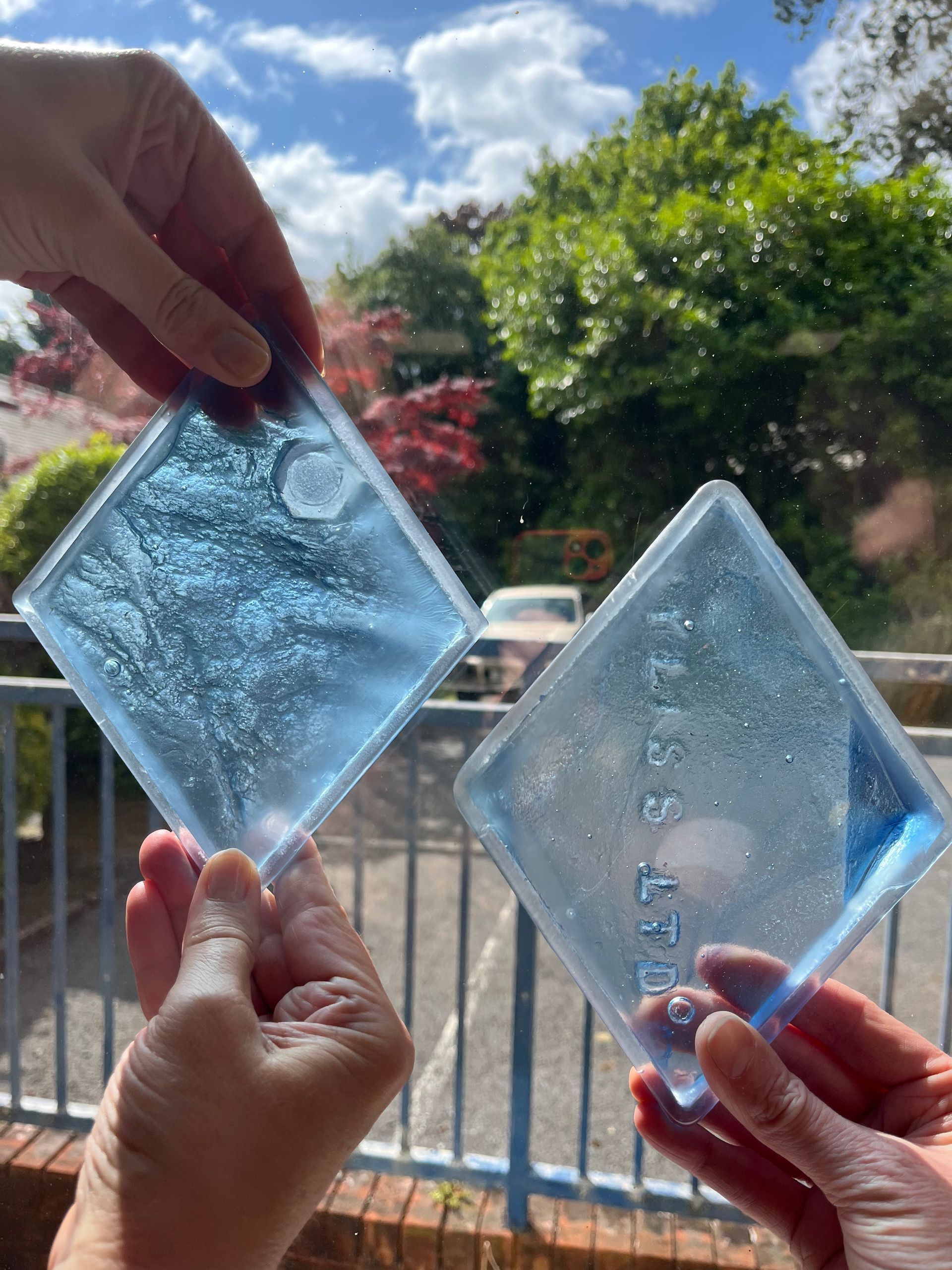

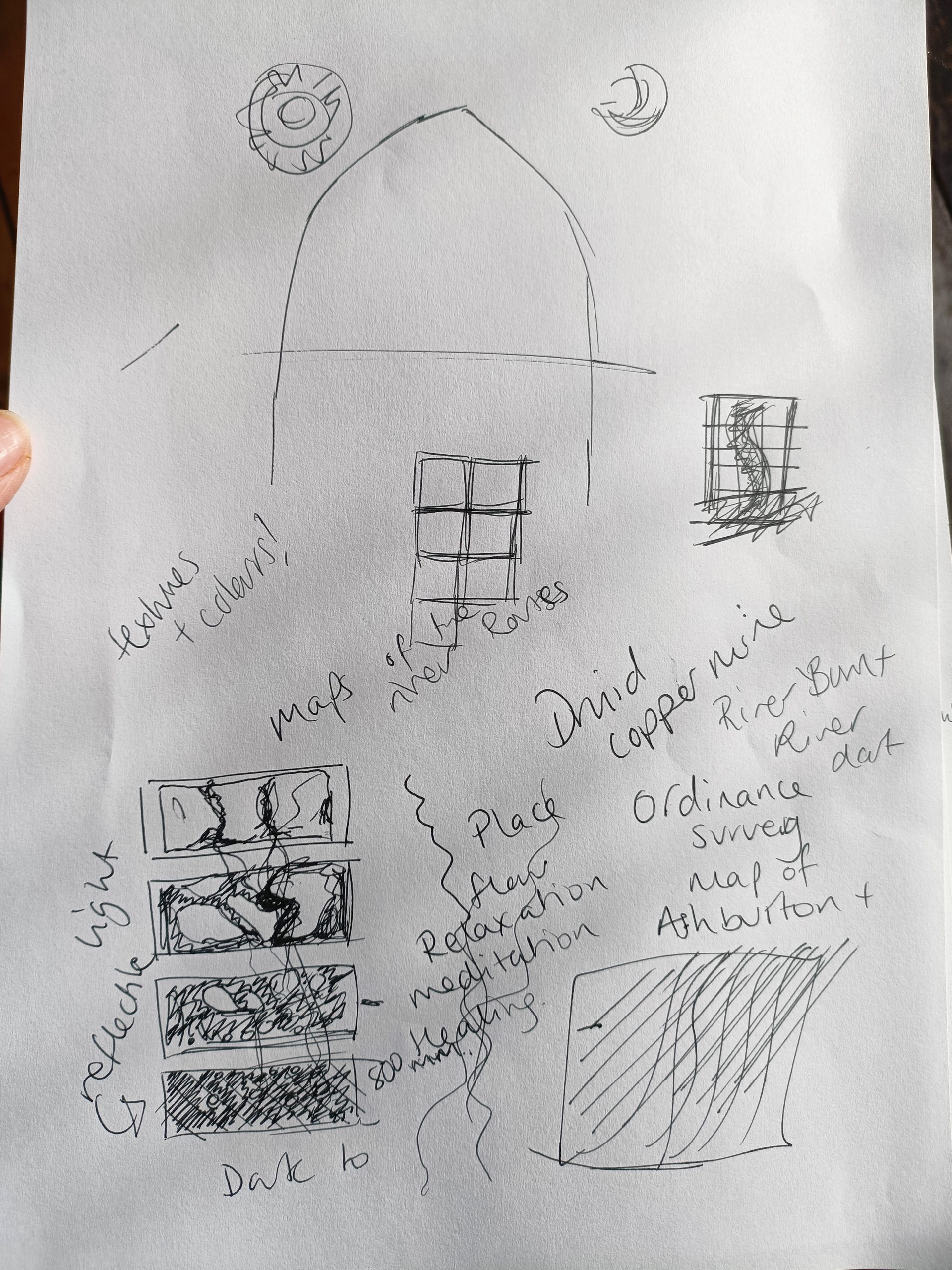

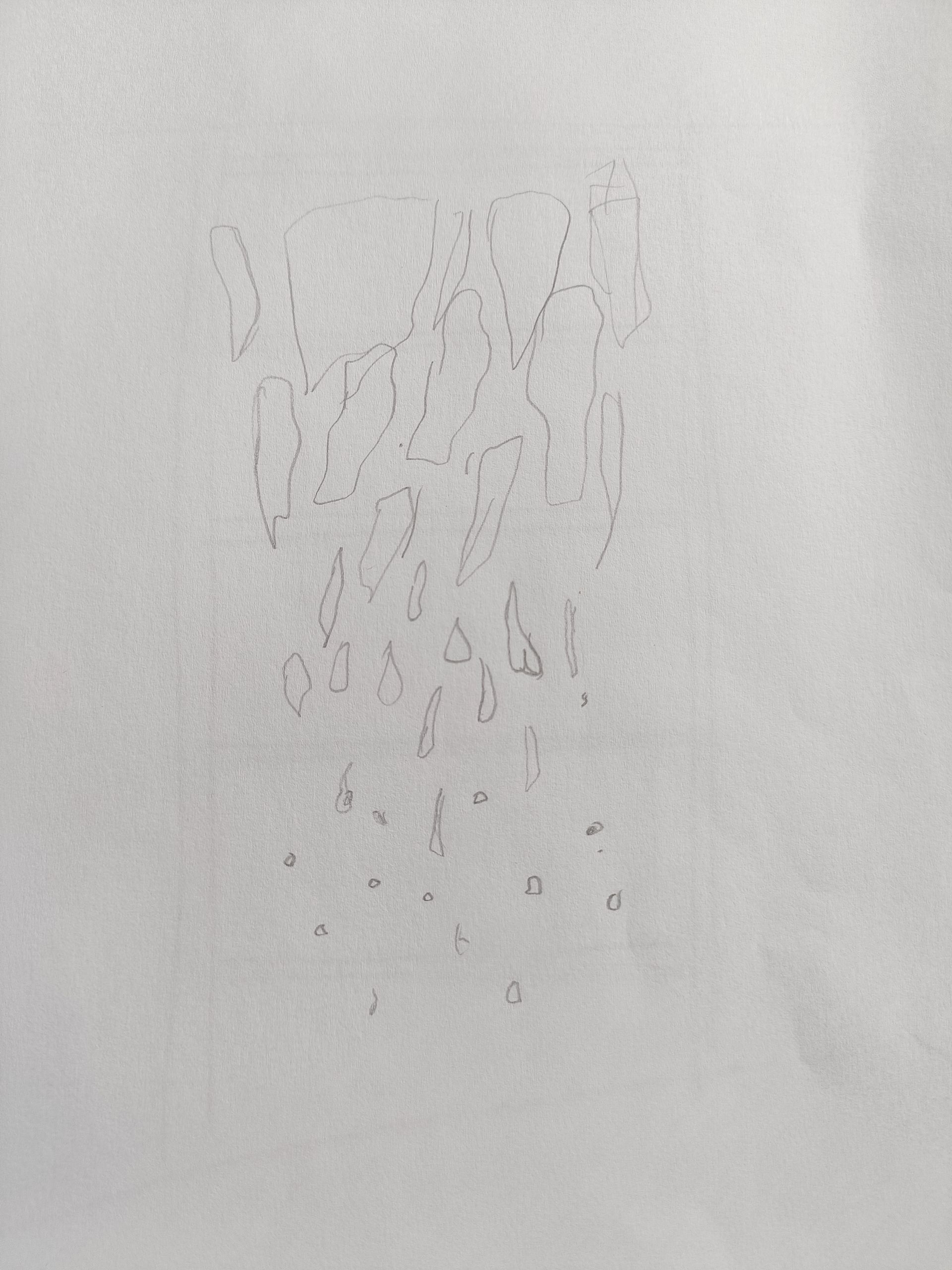

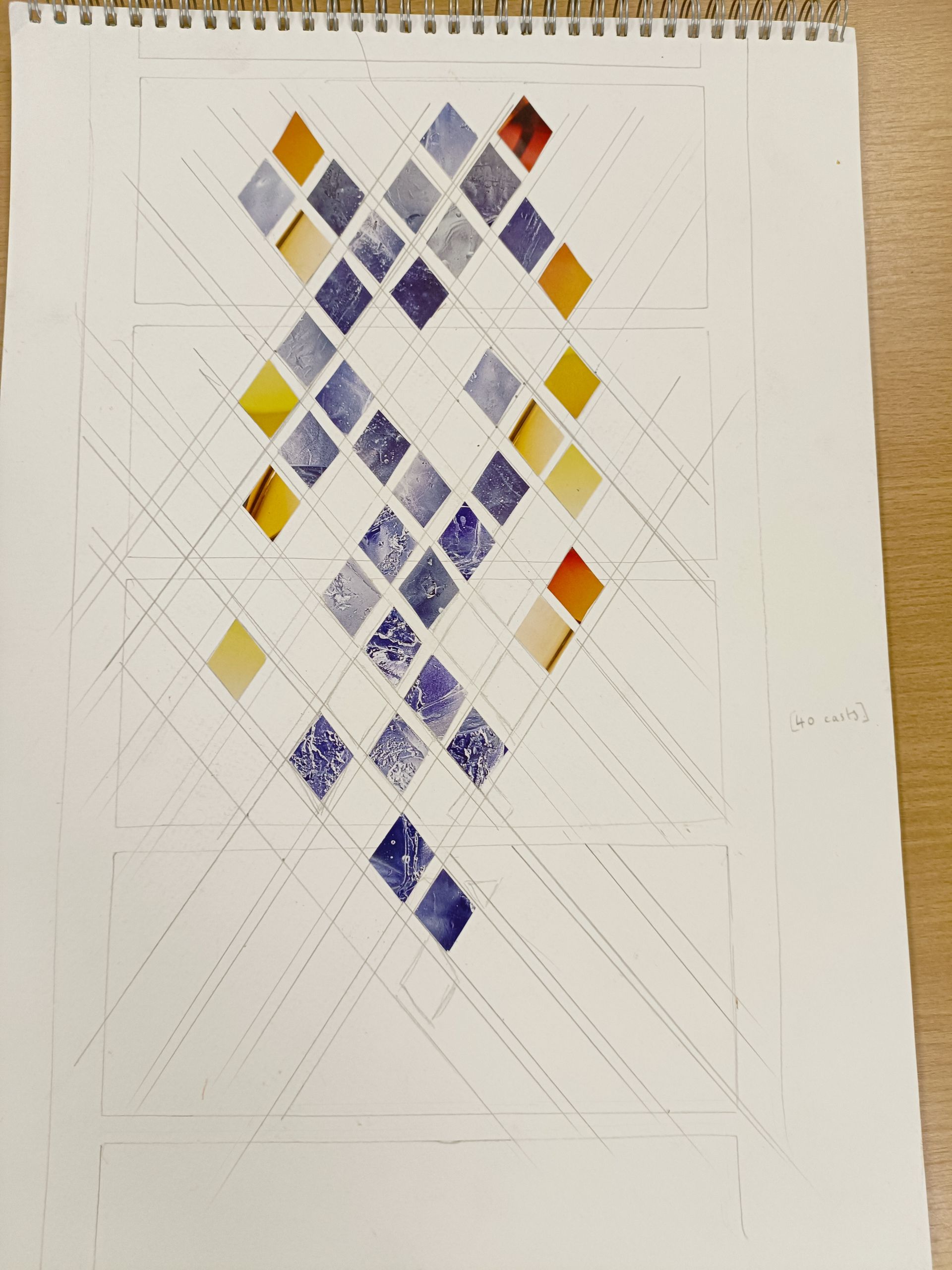

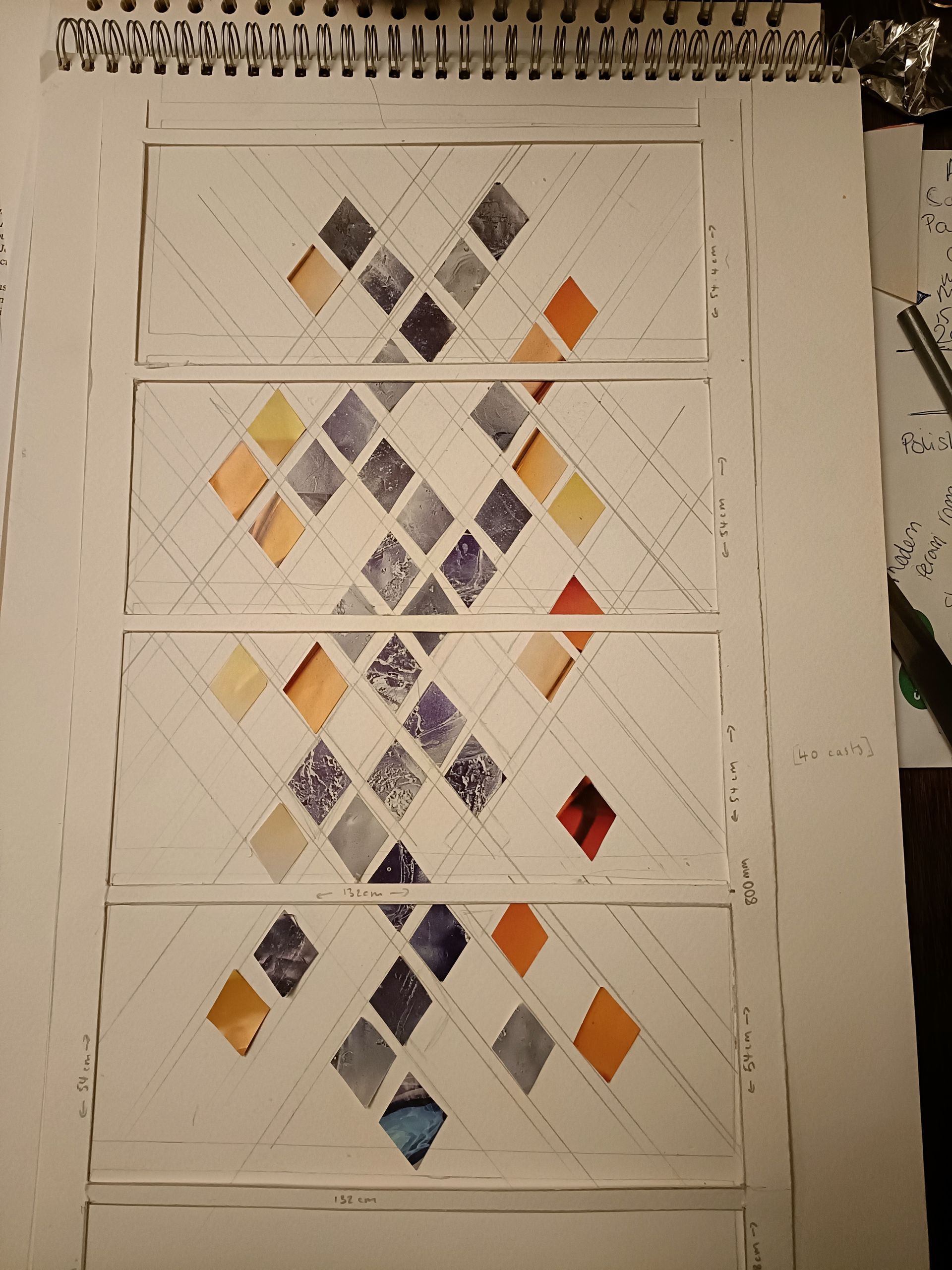

The design process takes quite a few forms, I did a lot of drawing, sketches, rough notes, and even paintings as I was developing my ideas. I knew that I wanted to capture the textures of the town, to celebrate the river and the dappled light through trees. I realised that I needed a repeatable shape to help me in the process of making as all of the textures would be different. Luckily glass in it's molten state behaves like water, it flows and fills the void that it is placed in. When solid glass reflects and refracts light similarly to water too, so some decisions were easy to make. Choosing to work with blues and yellows to represent the sun and the river. I had been able to purchase some beautiful light blue recycled glass from a studio, this immediately gave me a distinct colour to work with that wasn't off the shelf.

Quarry Diamonds are often the underappreciated hero in many stained glass leaded windows, the pattern they create whilst simple reflects light beautifully and provides order and elegance. Having visited the home of the Portreeve at St Lawrence's Chapel and seeing the traditional plain windows I wanted to champion this shape and use it as a repeating form within the entrance way.

As a cast glass artist I have used alginate, the product that dentists use to cast impressions of your teeth, I have used this to cast textures of objects and the space around them. Thinking of the glass as capturing a moment in time, whilst this object is still exposed to the elements and may continue to decay the texture on the glass will stay the same.

For this commission I was particularly keen to capture a central 'river' of textures. Textures of historical and local significance, from the surrounding areas from Ashburton to Buckfastleigh. Personally I prefer to view the text of an object through the glass, most of the diamonds have been cast in this way, as if there is a layer of glass over the top of the texture that has been captured.

There were some textures that I was keen to take that had to be replicated so that the texture was on the front surface of the panel and they could be touched. From top to bottom, the Bull ring found in