From Concept to Installation

Collaborating, Problem Solving, and Scaling Up

This commission came with unique technical and architectural challenges. Working within a public healthcare setting, there were strict safety standards I needed to meet. Glass, by its nature, must conform to building regulations around strength, lamination, and fixings. I had to ensure every element of the design would be secure, safe, and fully compliant—without compromising on beauty or detail.

I was incredibly fortunate to work alongside some experienced collaborators. Paul Ager, who has installed large-scale works for the Yorkshire Sculpture Park and Chatsworth House, advised me on connecting components and helped install the final piece. His knowledge of large artworks in architectural spaces was invaluable.

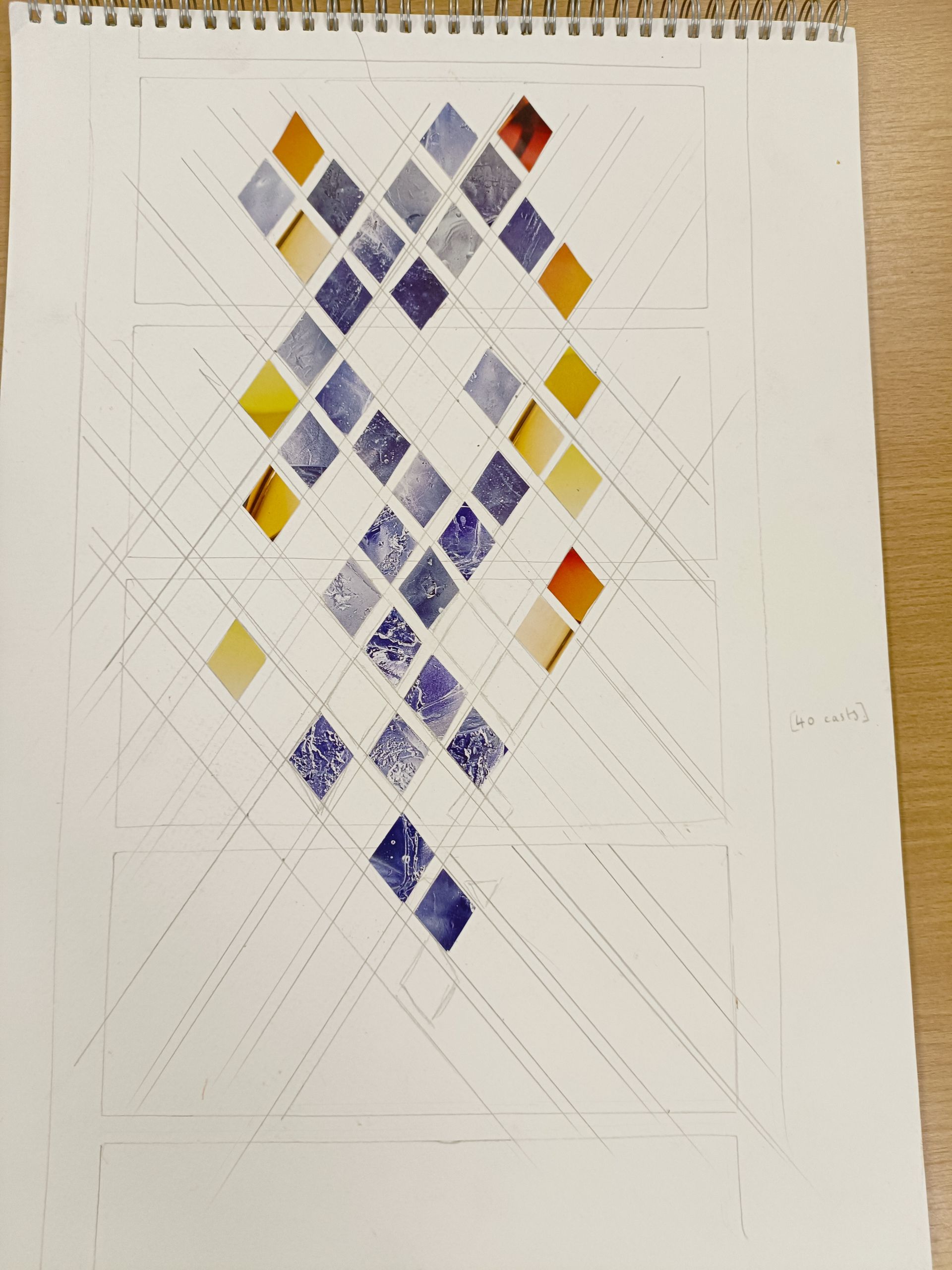

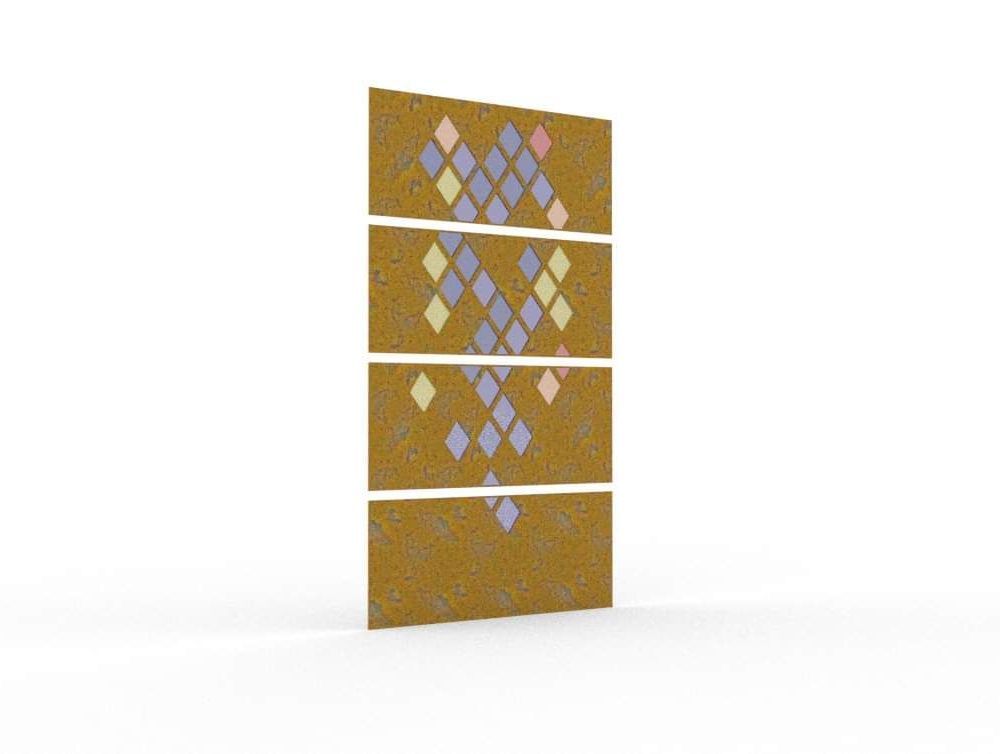

Another key part of the process was translating my hand-drawn, collaged design into something that could be fabricated precisely. Ian Hankey supported me in turning the concept into a detailed digital rendering something that could be used by Lazer Industries to cut the metalwork with precision.

Although I’ve worked in cast glass for many years, this was a step up in scale and complexity. I had to develop a completely new method for casting and fusing the glass so it would include a small lip, allowing it to sit securely within a layered steel framework. It took multiple rounds of testing and refinement—and even then, some panels needed cold-working at the end to achieve a perfect fit. It was a slow and meticulous process, but it taught me a lot.